+86 15633683072

The station adopts unified control. It includes total control system, equipment sub-control system and AGV control system. Production stations and product types can be combined freely. It has high production efficiency。

2. High automation level, high qualification rate and consistency.

The auto feeding system can realize steel pipe (rebar) cutting, automatic bending, automatic cutting of steel pipe arcs, etc. The custom fixtures replaces the manual assembly parts with mechanical devices. It assures accurate and reliable positioning and clamping. The workpiece is always in the best welding positio. It, effectively prevents and reduces welding deformation. The weld forming quality is good.

3. Available for multiple varieties, large quantities production.

The station uses a dual-station double robot to achieve full automatic welding. The robot has high utilization efficiency and low labor intensity. Weld efficiency is high. Defect rate is low. The overall production efficiency is 4-5 times compared with the manual.

4. High degree of information management, timely and efficient feedback on production activities

The line body control and visual management system are connected. All employees can learn the production status at any time. The production management board can fully reflect precise production and efficient management. The electronic method has flexible appearances. The content can be changed at any time. It can be fully used for production management in all fields.

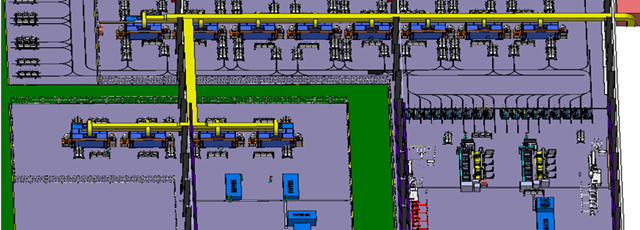

High automation level of Intelligent logistics, great utility. The workshop logistics system adopts AGV transportation. The overall control of material distribution is timely and reasonable. The AGV trolley intelligent collision avoidance system is safe and reliable. It reduces the need for stock preparation, assembly and other auxiliary workstations.

Unique safety and environmental protection design, dual pneumatic system. Active equipment safety protection is designed. It uses fully enclosed welding in the welding house. Smoke and dust purification system can realize smoke-free workshop. It reduces the damage of smoke and arc to the human body. The concentrated supply of carbon dioxide can save a lot of manual labor. It is about 20% less compared with the bottled gas.

The automatic discharging system can realize steel pipe discharging, steel bar discharging, automatic pipe bending, and automatic discharging of steel pipe arc. It realizes the high discharging precision and efficiency.

2.Flexible automatic welding system

Dual-station with dual robots are adopted to ensure fully automated welding. The system has feature of high robot utilization efficiency, low labor intensity, high welding efficiency, and low defect rate.

3.Safety and environmental protection system

The safety system includes the overall safety protection of the production line and equipment safety protection; the environmental protection system includes robotic welding fully enclosed and equipped with corresponding exhaust and dust removal systems.

4.Automated logistics system

The workshop logistics system uses AGV transportation to save labor. The system as a whole controls material distribution in a timely and reasonable manner, and the AGV trolley intelligent collision avoidance system is safe and reliable.

5.Visual production management system

Timely and efficient feedback of production activity information, realize information flow and logistics interaction management, lean production, efficient management, electronic method, flexible layout, content can be changed at any time, fully applicable to production management in different industries.

6.Dual pneumatic system

It includes compressed air system and carbon dioxide supply system. It could save 20% than bottled gas way.

7.The entire line of automation control system

The whole line control system is divided into the total control system, the equipment sub-control system, and the AGV control system. The type of production products can be combined at will, flexible and changeable. The connection between the line body control and the visual management system allows all employees to keep abreast of the production status and truly realize information management.

The station uses 24 industrial welding robots, 12 sets of workstations, 2 automatic laser cutting machines, 2 automatic punching machines, 3 automatic pipe cutting machines, 4 sets of intelligent AGV trolley logistics handling systems, and 5 automatic bending machines. Pipe machine, smoking dust removal system, dual gas path centralized gas supply system, visual management system and central centralized control system.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com